FLANDS FROM THE RUNNING STAY IN THE FIRST

Connections with flanges are durable, reliable and durable. Stainless steel flanges can operate in aggressive environments, in conditions of high pressure and temperature, various mechanical loads (vibration, shock, etc.). Flange connections are widespread in pipelines, mechanisms and structures.

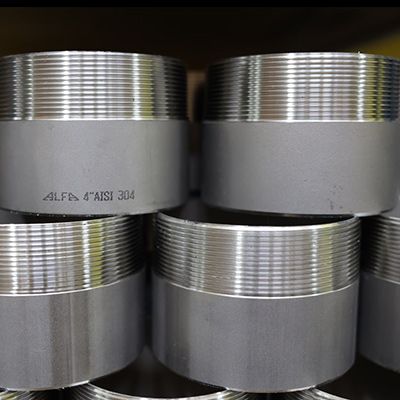

FLANTS FROM COMPANY ALFA-STAR

We offer AISI 304, AISI 316, 12X18N10T stainless steel flanges, 10X17H13M2T of high quality of the following types:

- welded flanges DIN and GOST. They are welded with two seams to the ends of the pipes, then a gasket is installed between the flanges, ensuring the tightness and uniformity of the pressure distribution. The connection is tightened with bolts or studies. Work at a pressure of up to 2.5 MPa;

- collar flanges DIN and GOST. They are welded to the end of the pipe with a collar cake - a cone-shaped protrusion. A pair of flanges is tightened. The resulting compound has almost complete tightness, withstanding pressure up to 40 MPa;

- free flanges are stainless and silomine. The connecting node with free flanges includes a pair of collars. Free flanges are put on the ends of the pipes, collar cakes are welded to the ends of the pipes, and then free flanges are pulled off with a fastener. Such connections are installed on hard-to-reach sections of the pipeline that need frequent repair and maintenance. For areas where pressure does not exceed 1 MPa, you can use cheaper silomine flanges;

- DIN and GOST flange plugs blocking the operating flow;

- flange gaskets of steel and non-metallic DIN and GOST. Steel gaskets are installed in the responsible sections of the pipeline, in less stressed areas - paronite, Teflon, EPDM.